Binciken dalilai na matsalolin rashin ruwa na gypsum

1 Ciyarwar mai na tukunyar jirgi da barga mai konewa

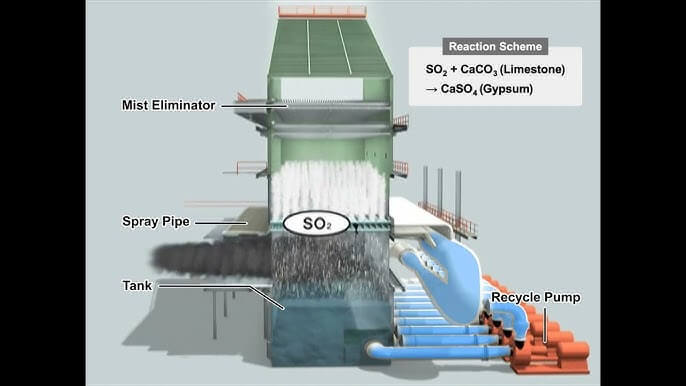

Matakan samar da wutar lantarki na kwal suna buƙatar cinye man fetur mai yawa don taimakawa konewa yayin farawa, rufewa, konewa mai ƙarancin nauyi da ƙa'ida mai zurfi saboda ƙira da kona kwal. Saboda rashin aiki mai ƙarfi da ƙarancin konewar tukunyar jirgi, babban adadin man da ba a kone ba ko cakuda foda mai zai shiga slurry na abin sha tare da iskar gas. Ƙarƙashin tashin hankali mai ƙarfi a cikin abin sha, yana da sauƙi don samar da kumfa mai kyau kuma a tattara a saman slurry. Wannan shi ne nazarin abun da ke ciki na kumfa a saman slurry mai ɗaukar wutar lantarki.

Yayin da man ke taruwa a saman slurry, wani sashi nasa da sauri ya watse a cikin slurry absorber a ƙarƙashin hulɗar motsawa da fesa, kuma an kafa fim ɗin mai na bakin ciki a saman dutsen farar ƙasa, calcium sulfite da sauran barbashi a cikin slurry, wanda ke nannade farar ƙasa da sauran barbashi, yana hana allistone da rushewar lime. desulfurization yadda ya dace da kuma samuwar gypsum. Ruwan hasumiya mai ɗauke da mai yana shiga cikin tsarin bushewar gypsum ta famfon fitarwa na gypsum. Saboda kasancewar mai da samfuran sulfurous acid ɗin da ba su cika cika ba, yana da sauƙi a toshe tazarar bel ɗin jigilar matattara, wanda ke haifar da matsaloli a cikin bushewar gypsum.

2.Tsokawar Hayaki a Mashigar Ruwa

Hasumiyar shayar da ruwa ta rigar tana da takamaiman tasirin kawar da ƙura, kuma ingancin cirewar ƙura na iya kaiwa kusan 70%. An ƙera tashar wutar lantarki don samun ƙurar ƙura na 20mg/m3 a mashigar tattara ƙura (shigarwa na desulfurization). Domin adana makamashi da rage amfani da wutar lantarki na shuka, ana sarrafa ainihin ƙurar ƙura a mashin tattara ƙura a kusan 30mg/m3. Ƙarar ƙura mai yawa ta shiga hasumiya mai sha kuma an cire shi ta hanyar kawar da ƙurar haɗin gwiwa na tsarin desulfurization. Yawancin barbashin ƙurar da ke shiga hasumiya ta sha bayan tsabtace ƙurar lantarki ba su kai 10μm ba, ko ma ƙasa da 2.5μm, wanda ya fi ƙanƙanta girman barbashi na gypsum slurry. Bayan kura ta shiga injin bel ɗin injin tare da gypsum slurry, kuma tana toshe rigar tacewa, wanda ke haifar da rashin kyallen iska daga rigar tacewa da wahalar bushewar gypsum.

2. Tasirin ingancin gypsum slurry

1 Slurry yawa

Girman slurry yawa yana nuna yawan slurry a cikin hasumiya mai sha. Idan yawancin ya yi ƙanƙara, yana nufin cewa abun ciki na CaSO4 a cikin slurry yana da ƙananan kuma abun ciki na CaCO3 yana da girma, wanda ke haifar da asarar CaCO3 kai tsaye. A lokaci guda, saboda ƙananan ƙwayoyin CaCO3, yana da sauƙi don haifar da matsalolin rashin ruwa na gypsum; idan slurry yawa yana da girma, yana nufin cewa abun ciki na CaSO4 a cikin slurry yana da girma. Mafi girma CaSO4 zai hana rushewar CaCO3 kuma ya hana sha na SO2. CaCO3 yana shiga cikin tsarin bushewar ruwa tare da gypsum slurry kuma yana rinjayar tasirin rashin ruwa na gypsum. Domin ya ba da cikakken wasa ga fa'idodin tsarin kewayawa biyu na hasumiya biyu na iskar gas mai lalata ruwa, ƙimar pH na hasumiya ta farko ya kamata a sarrafa shi a cikin kewayon 5.0 ± 0.2, kuma ya kamata a sarrafa ƙarancin slurry a cikin kewayon 1100 ± 20kg / m3. A cikin ainihin aiki, slurry yawa na matakin farko na hasumiya na shuka shine kusan 1200kg / m3, har ma ya kai 1300kg / m3 a lokuta masu girma, wanda koyaushe ana sarrafa shi a babban matakin.

2. Degree na tilasta hadawan abu da iskar shaka na slurry

Tilasta iskar shaka na slurry shine gabatar da isasshen iska a cikin slurry don sanya iskar shaka na calcium sulfite zuwa alli sulfate dauki yakan zama cikakke, kuma adadin iskar shaka ya fi 95%, yana tabbatar da cewa akwai isassun nau'ikan gypsum a cikin slurry don girma crystal. Idan oxidation bai isa ba, gauraye lu'ulu'u na alli sulfite da calcium sulfate za a samar, haifar da scaling. Matsayin tilasta oxidation na slurry ya dogara da dalilai kamar adadin iskar iskar shaka, lokacin zama na slurry, da tasirin motsa jiki na slurry. Rashin isashshen iskar iskar shaka, ɗan gajeren lokacin zama na slurry, rashin daidaituwa na rarraba slurry, da mummunan tasirin motsa jiki duk zai haifar da abun ciki na CaSO3 · 1/2H2O a cikin hasumiya ya yi tsayi da yawa. Ana iya ganin cewa saboda rashin isashshen iskar oxygen na gida, abun ciki na CaSO3 · 1 / 2H2O a cikin slurry yana da mahimmanci mafi girma, yana haifar da wahala a cikin gypsum dehydration da babban abun ciki na ruwa.

3. Abubuwan da ke cikin najasa a cikin slurry Abubuwan da ke cikin slurry sun fi fitowa daga iskar hayaƙi da farar ƙasa. Waɗannan ƙazanta suna haifar da ions na ƙazanta a cikin slurry, suna shafar tsarin lattice na gypsum. Karafa masu nauyi da ke ci gaba da narkar da su a cikin hayaki zai hana amsawar Ca2+ da HSO3-. Lokacin da abun ciki na F- da Al3 + a cikin slurry ya yi girma, za a samar da fluorine-aluminum hadaddun AlFn, yana rufe saman ɓangarorin limestone, haifar da guba mai guba, rage haɓakar desulfurization, kuma an gauraya ɓangarorin limestone mai kyau a cikin lu'ulu'u na gypsum da ba su cika cika ba, yana sa ya zama da wahala a dehydrate. Cl- in slurry yafi fitowa daga HCl a cikin iskar gas da sarrafa ruwa. Abubuwan da ke cikin Cl-in da ke cikin ruwa kaɗan ne, don haka Cl- in slurry galibi yana fitowa ne daga iskar hayaƙi. Lokacin da akwai babban adadin Cl- in slurry, Cl- za a naɗe shi da lu'ulu'u kuma a haɗa shi da wani adadin Ca2+ a cikin slurry don samar da tsayayyen CaCl2, yana barin wani adadin ruwa a cikin lu'ulu'u. A lokaci guda, wani adadin CaCl2 a cikin slurry zai kasance tsakanin lu'ulu'u na gypsum, yana toshe tashar ruwan kyauta tsakanin lu'ulu'u, haifar da abun ciki na ruwa na gypsum ya karu.

3. Tasirin matsayin aikin kayan aiki

1. Gypsum slurry tsarin gypsum slurry Ana yin famfo zuwa gypsum cyclone don rashin ruwa na farko ta hanyar famfo na gypsum. Lokacin da slurry na ƙasa ya maida hankali zuwa ingantaccen abun ciki na kusan 50%, yana gudana zuwa injin bel ɗin don rashin ruwa na biyu. Babban abubuwan da ke shafar tasirin rabuwa na gypsum cyclone sune matsa lamba mai shiga cikin guguwar da girman yashi mai daidaita bututun ruwa. Idan matsa lamba mai shiga cyclone ya yi ƙasa da ƙasa, tasirin rabuwa mai ƙarfi-ruwa zai zama mara kyau, slurry na ƙasa zai sami ƙarancin abun ciki mai ƙarfi, wanda zai shafi tasirin dehydration na gypsum kuma yana ƙara yawan ruwa; idan matsa lamba mashigai na cyclone ya yi yawa, tasirin rabuwa zai fi kyau, amma zai shafi tasirin rarraba guguwar kuma ya haifar da lalacewa mai tsanani akan kayan aiki. Idan girman bututun gyaran yashi ya yi girma da yawa, hakanan zai haifar da slurry na ƙasa ya sami ƙarancin abun ciki mai ƙarfi da ƙarami, wanda zai shafi tasirin bushewar injin bel ɗin.

Maɗaukaki ko ƙanƙara mai yawa zai shafi tasirin gypsum dehydration. Idan injin ya yi ƙasa sosai, ikon cire danshi daga gypsum zai ragu, kuma tasirin gypsum dehydration zai zama mafi muni; idan injin ya yi tsayi da yawa, za a iya toshe ramukan da ke cikin rigar tacewa ko kuma bel ɗin zai iya karkata, wanda kuma zai haifar da mummunan sakamako na bushewar gypsum. A ƙarƙashin yanayin aiki iri ɗaya, mafi kyawun ƙarancin iska na zanen tacewa, mafi kyawun tasirin gypsum dehydration; idan yanayin iska na zanen tace ba shi da kyau kuma an toshe tashar tacewa, tasirin gypsum dehydration zai zama mafi muni. Kaurin kek ɗin tace shima yana da tasiri sosai akan bushewar gypsum. Lokacin da saurin isar bel ɗin ya ragu, kaurin kek ɗin tace yana ƙaruwa, kuma ikon injin famfo na cire saman saman kek ɗin ya yi rauni, wanda ke haifar da haɓakar ɗanɗanon gypsum; lokacin da saurin isar bel ɗin ya ƙaru, kaurin kek ɗin tacewa yana raguwa, wanda ke da sauƙin haifar da ɗigowar tacewa na gida, yana lalata injin, sannan kuma yana haifar da haɓakar ɗanɗanon gypsum.

2. Rashin aiki mara kyau na desulfurization tsarin kula da ruwa na ruwa ko ƙananan ƙwayar jiyya na ruwa zai shafi zubar da ruwa na yau da kullum na desulfurization. A karkashin dogon lokaci aiki, ƙazanta kamar hayaki da ƙura za su ci gaba da shiga cikin slurry, da kuma nauyi karafa, Cl-, F-, Al-, da dai sauransu a cikin slurry za su ci gaba da wadatar, sakamakon ci gaba da deterioration na slurry quality, shafi al'ada ci gaban desulfurization dauki, gypsum samuwar da dehydration. Ɗaukar Cl-in slurry a matsayin misali, abun ciki na Cl- abun ciki a cikin slurry na matakin farko na hasumiya na wutar lantarki ya kai 22000mg/L, kuma Cl- abun ciki a gypsum ya kai 0.37%. Lokacin da abun ciki na Cl-a cikin slurry ya kai kusan 4300mg/L, tasirin gypsum na bushewa ya fi kyau. Yayin da abun ciki na ion chloride ya karu, sakamakon rashin ruwa na gypsum yana raguwa a hankali.

Matakan sarrafawa

1. Ƙarfafa konewa daidaitawar tukunyar jirgi aiki, rage tasirin man allura da barga konewa a kan desulfurization tsarin a lokacin farawa-up da kuma rufe mataki na tukunyar jirgi ko low-load aiki, sarrafa yawan slurry wurare dabam dabam farashinsa sa a cikin aiki, da kuma rage gurbatawa na unburned man foda cakuda ga slurry.

2. La'akari da dogon lokacin da barga aiki da kuma overall tattalin arziki na desulfurization tsarin, ƙarfafa aiki daidaitawa na ƙura tara, dauko high siga aiki, da kuma sarrafa ƙura taro a ƙura tara kanti (desulfurization mashiga) a cikin zane darajar.

3. Ainihin saka idanu na slurry yawa (slurry yawa mitaoxidation iska girma, sha hasumiya ruwa matakin (radar matakin mitaslurry stirring na'urar, da dai sauransu don tabbatar da cewa desulfurization dauki ne da za'ayi a karkashin al'ada yanayi.

4. Ƙarfafa kiyayewa da daidaitawa na gypsum cyclone da ƙwanƙwasa bel, kula da matsa lamba na gypsum cyclone da kuma digiri na bel na jigilar bel a cikin ma'auni mai ma'ana, kuma a kai a kai duba cyclone, yashi na kwancen yashi da zane mai tacewa don tabbatar da cewa kayan aiki suna aiki a cikin mafi kyawun yanayin.

5. Tabbatar da al'ada aiki na desulfurization sharar gida magani tsarin, akai-akai sallama da desulfurization sharar gida ruwa, da kuma rage najasa abun ciki a cikin sha hasumiya slurry.

Kammalawa

Wahalar rashin ruwa na gypsum matsala ce ta kowa a cikin kayan aikin desulfurization na rigar. Akwai abubuwa da yawa masu tasiri, waɗanda ke buƙatar cikakken bincike da daidaitawa daga bangarori da yawa kamar kafofin watsa labarai na waje, yanayin amsawa da matsayin aikin kayan aiki. Sai kawai ta hanyar zurfin fahimtar tsarin amsawar desulfurization da halayen aikin kayan aiki da kuma sarrafa ma'auni mai mahimmanci na tsarin za a iya tabbatar da tasirin bushewa na gypsum desulfurized.

Lokacin aikawa: Fabrairu-06-2025