Thekira na formaldehyde, wani muhimmin tsari a cikin masana'antu, yana buƙatar daidaitaccen iko akan ƙididdigar layin layi na methanol da formaldehyde don tabbatar da ingancin samfur, ingantaccen aiki, da bin ka'idoji. Formaldehyde, wanda aka samar ta hanyar iskar oxygen da iskar shaka na methanol, shine babban sashi a cikin resins, adhesives, robobi, da magunguna, amma har ma da ƴan sabani a cikinmethanol maida hankalikoformaldehyde maida hankalina iya haifar da polymerization, rage yawan amfanin ƙasa, ko rashin bin ƙa'idodin aminci.

Methanol maida hankali firikwensin,formaldehyde maida hankali mita,formaldehyde maida hankali, kumaformaldehyde maida hankali analyzersba da sahihancin sa ido, ba da damar masu aikin shuka su kula da mafi kyawun yanayi da kuma rage ƙarancin inganci.

Gabaɗaya Gabatarwar Tsarin Sinadarai

Formaldehyde, wani nau'in sinadari iri-iri da ake amfani da shi a cikin komai daga mannen itace zuwa tsaka-tsakin magunguna, ana samar da shi ta hanyar oxidation na methanol a cikin tsire-tsire na formaldehyde. Tsayawa daidaitaccen maida hankali na methanol da taro na formaldehyde yana da mahimmanci don saduwa da ingantattun matakan inganci.

Methanol maida hankali na'urori masu auna firikwensin da formaldehyde taro analyzers su ne makawa kayan aiki don cimma wannan daidaici. Waɗannan na'urori suna ba da bayanan lokaci-lokaci, kawar da jinkiri da kurakurai masu alaƙa da samfurin hannu, da baiwa masu aiki damar haɓaka yanayin amsawa, rage sharar gida, da tabbatar da bin ƙa'idodin muhalli da aminci.

Chemistry da Tsarin Formaldehyde Synthesis

Haɗin haɓakar formaldehyde ya haɗa da iskar oxygenation na methanol, tsarin da aka tace shekaru da yawa don biyan buƙatun masana'antu kamar masana'antar sinadarai da magunguna. Wannan exothermic dauki yana catalyzed ta ko dai azurfa ko baƙin ƙarfe-molybdenum, tare da methanol tururi gauraye da iska da kuma wuce a kan mai kara kuzari a cikin reactor.

Sakamakon formaldehyde yana shiga cikin wani bayani mai ruwa, sau da yawa yana daidaitawa tare da 10-15% methanol don hana polymerization zuwa paraformaldehyde. Tsarin yana buƙatar daidaitaccen sarrafa ƙwayar methanol a cikin kayan abinci da tattarawar formaldehyde a cikin reactor da samfurin ƙarshe don tabbatar da yawan amfanin ƙasa.

Mahimmin matakai sun haɗa da:

Methanol Shiri

Tabbatar da kayan abinci yana da daidaitaccen ma'aunin methanol mai ruwa (yawanci 50-60 wt%) don haɓaka ingancin amsawa.

Oxidation

Sarrafa ma'aunin methanol-iska da yanayin reactor don haɓaka samar da formaldehyde da rage abubuwan da suka dace kamar formic acid.

Sha

Shigar da formaldehyde cikin ruwa don samar da formalin, yana buƙatar daidaitaccen ma'aunin taro na formaldehyde don hana polymerization.

Adana da Tsayawa

Ƙara methanol stabilizers don kula da taro na formaldehyde da hana lalacewa.

Me yasa Sarrafa Mahimmanci na cikin layi yana da mahimmanci

Tsayawa daidaitaccen ma'auni na methanol da ma'aunin taro na formaldehyde yana da mahimmanci don dalilai da yawa. Yawan methanol a cikin kayan abinci na iya haifar da rashin isashshen iskar oxygen, rage yawan amfanin formaldehyde da haɓaka sharar gida. Sabanin haka, rashin isasshen methanol na iya haifar da yunwar, rage yawan aiki. A cikin matakin sha, babban adadin formaldehyde (sama da 50 wt%) yana haɗarin polymerization, samar da daskararrun paraformaldehyde wanda ke toshe kayan aiki da rushe ayyukan.

Hanyoyin sa ido na al'ada, irin su chromatography gas na layi ko titration, suna ɗaukar lokaci kuma suna iya fuskantar kurakurai, jinkirta ayyukan gyara. Methanol maida hankali na'urori masu auna firikwensin da formaldehyde taro saka idanu samar da ci gaba, real-lokaci bayanai, kunna masu aiki don daidaita feedstock rabo, reactor yanayi, da stabilizer kari nan take, tabbatar da daidaito samfurin ingancin da kuma aiki yadda ya dace.

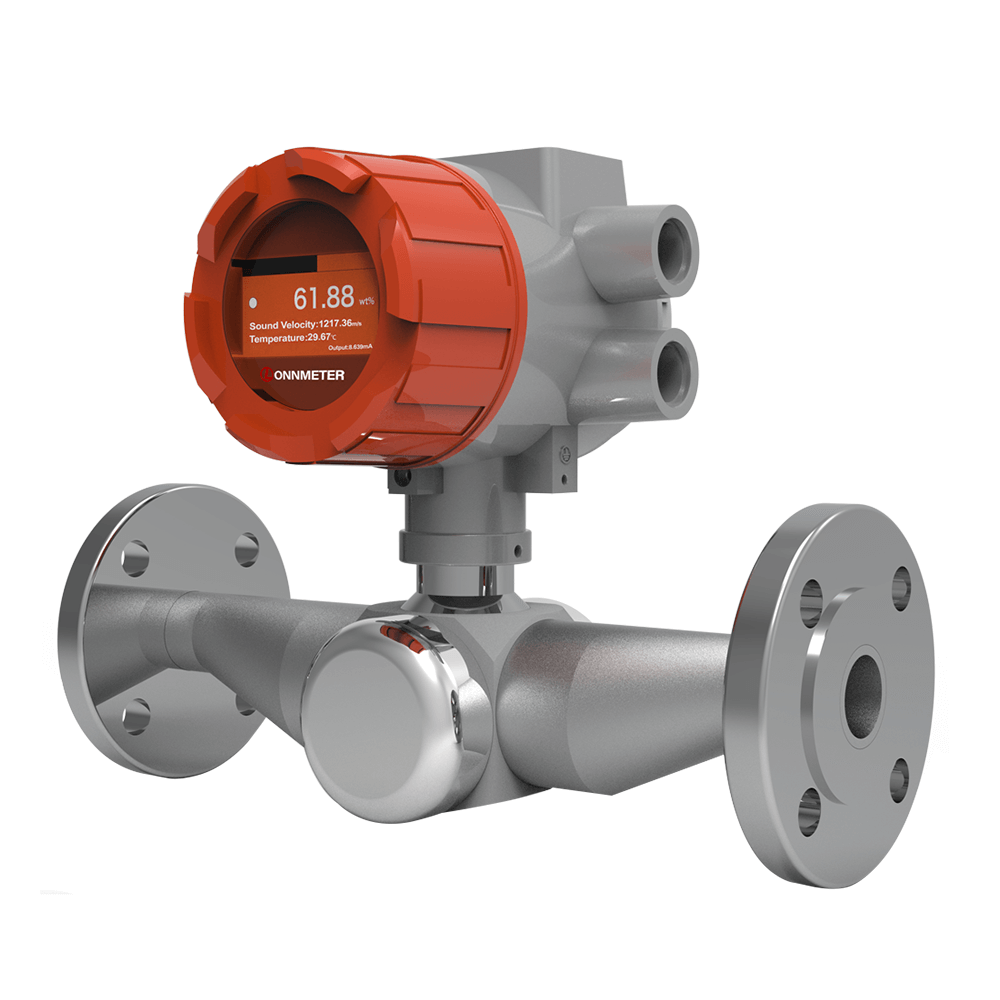

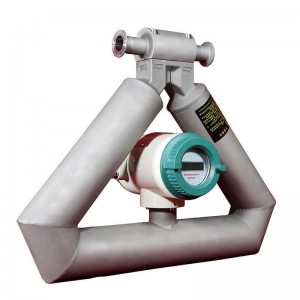

Shawarar Lonnmeter Inline Concentration Monitor

Mitar maida hankali na Lonnmeter ultrasonic yana aiki ta hanyar auna lokacin watsawa na raƙuman ruwa na ultrasonic daga tushen siginar zuwa mai karɓa, yana nuna saurin sauti don ƙididdige yawa da tattarawa. Wannan hanyar ba ta da tasiri ta kumfa, kumfa, ko tafiyar da ruwa, launi, ko bayyananne, yana tabbatar da babban dogaro a cikin mahalli masu ƙalubale kamar tsire-tsire na samar da formaldehyde.

Rashin sassan motsi yana kawar da lalacewa na inji, yana tabbatar da daidaiton aiki akan lokaci. Ƙirar mitar da ba ta da hankali tana rage gyare-gyare, kuma kayan da ke jure lalata suna jure wa sinadarai masu haɗari, yana sa ya dace da tsire-tsire masu magani don magance formaldehyde da methanol.

Dabarun Shigarwa da Haɗin kai

Don haɓaka tasiri na masu nazarin taro na formaldehyde, shigarwa dabarun yana da mahimmanci. Ya kamata a sanya na'urori masu auna firikwensin methanol a cikin layukan abinci don tabbatar da daidaiton ingancin shigarwa, yayin da matakan tattarawar formaldehyde sun dace don kantunan reactor da ginshiƙan sha don sa ido kan samuwar samfur da daidaitawa. Za a iya ƙaddamar da tsarin da aka yi amfani da su don ci gaba da aiki a lokacin kulawa, rage raguwa.

Haɗin kai tare da tsarin sarrafa tsire-tsire yana ba da damar yin gyare-gyare ta atomatik, kamar daidaita ƙimar abinci na methanol ko ƙari mai daidaitawa, dangane da bayanan ainihin lokaci. Daidaitawa na yau da kullun tare da daidaitattun mafita yana tabbatar da daidaiton ma'auni, musamman a cikin yanayi mai ƙarfi na haɗin formaldehyde.

Fa'idodin Mitar Tattara Layi na Lonnmeter

Haɓaka Ingantacciyar Aiki

Ɗaukar na'urori masu auna firikwensin methanol da na'urorin saka idanu na formaldehyde suna inganta ingantaccen aiki a cikin tsire-tsire masu samar da formaldehyde. Ta hanyar samar da bayanan lokaci-lokaci, waɗannan na'urori suna ba masu aiki damar ganowa da kuma daidaita karkatar da hankali nan take, rage haɗarin rushewar tsari. Misali, kiyaye mafi kyawun maida hankali na methanol mai ruwa a cikin kayan abinci yana hana iskar oxygen da bai cika ba, haɓaka yawan amfanin ƙasa da rage sharar gida. Hakazalika, daidaitaccen ma'aunin taro na formaldehyde a cikin matakin sha yana hana polymerization, rage lalata kayan aiki da ƙimar kulawa.

A cikin tsire-tsire na petrochemical, waɗannan kayan aikin suna haɓaka amfani da methanol, rage farashin kayan abinci, yayin da a cikin tsire-tsire na magunguna, suna tabbatar da daidaiton matsakaicin inganci, rage sake yin aiki. Kididdigar masana'antu sun ba da shawarar cewa sa ido kan layi na iya rage yawan amfani da makamashi har zuwa 10% kuma yana adana mahimman lokacin aiki ta sarrafa sarrafa ayyukan bincike.

Tabbatar da Ingancin Samfur da Biyayya

Kayayyakin tushen formaldehyde, irin su urea-formaldehyde resins da masu tsaka-tsakin magunguna, dole ne su dace da ingantacciyar inganci da ka'idojin aminci. Formaldehyde masu nazarin hankali suna tabbatar da cewa samfurin ƙarshe (misali, formalin) yana kula da daidaitattun daidaito (37-50 wt%) da abun ciki mai daidaitawa, hana lalacewa da tabbatar da aiki a aikace-aikace kamar adhesives da sutura.

Dokokin muhalli, waɗanda gubar formaldehyde ke motsa su, suna buƙatar tsauraran matakan sarrafawa. Mitoci na kan layi suna taimaka wa tsire-tsire su sa ido da rage hayakin formaldehyde, rage haɗarin tara da haɓaka dorewa. Wannan yana da mahimmanci musamman a cikin tsire-tsire na petrochemical, inda manyan samarwa ke haɓaka tasirin muhalli.

Tashin Kuɗi da Ƙimar Dogon Lokaci

Fa'idodin kuɗi na mitoci na taro na formaldehyde suna da yawa. Ta hanyar saka idanu ta atomatik, waɗannan na'urori suna rage farashin aiki mai alaƙa da samfurin hannu, mai yuwuwar ceton sa'o'i kowace rana a cikin manyan ayyuka. Har ila yau, suna rage sharar gida ta hanyar hana yawan amfani da methanol da stabilizers fiye da ko ƙasa, inganta amfani da kayan abinci. Ana samun tanadin makamashi ta hanyar kiyaye mafi kyawun yanayin amsawa, rage buƙatar dumama zafi ko sanyaya a cikin reactors da raka'a sha.

Tsawon waɗannan mitoci, waɗanda aka gina tare da kayan juriya na lalata, yana tabbatar da dogaro na dogon lokaci a cikin matsanancin yanayi na haɗakar formaldehyde. Ƙananan buƙatun kulawa da haɗin kai tare da tsarin sarrafawa ya sa su zama jari mai tasiri mai tsada don masana'antun masana'antun sinadarai da tsire-tsire masu tsire-tsire masu neman haɓaka riba.

Zaɓin firikwensin maida hankali na methanol ko formaldehyde mai nazarin taro yana buƙatar yin la'akari da hankali na abubuwa kamar daidaito, zafin jiki, hanyar shigarwa, kayan, da sauransu.

FAQs

Ta yaya Methanol Concentration Sensors ke haɓaka Haɗin Formaldehyde?

Na'urori masu auna firikwensin methanol suna ba da sa ido na ainihin lokacin ingancin kayan abinci, yana tabbatar da mafi kyawun ma'aunin taro na methanol don ingantaccen iskar oxygen mai ƙarfi. Wannan yana hana halayen da basu cika ba kuma yana haɓaka yawan amfanin ƙasa a cikin tsire-tsire masu samar da formaldehyde, haɓaka daidaiton samfur.

Menene Fa'idodin Nazari Masu Tattaunawa na Formaldehyde?

Masu nazarin taro na formaldehyde suna tabbatar da ma'aunin ma'auni na ma'auni na formaldehyde, hana polymerization da tabbatar da bin iyakokin tsari. Suna rage sharar gida da kuma inganta inganci a masana'antar kera sinadarai da masana'antar harhada magunguna.

Shin Mitar Haɗin Kan Layi Za Su Iya Jure Yanayin Haɗin Formaldehyde?

An ƙera na'urori masu saka idanu na zamani na formaldehyde don yin aiki da dogaro a ƙarƙashin yanayin zafi mai zafi da lalata yanayin haɗin formaldehyde. Gina tare da kayan aiki masu ƙarfi, suna tabbatar da aiki na dogon lokaci da sa ido daidai.

Methanol maida hankali firikwensin, formaldehydemita maida hankali, masu saka idanu, da masu nazari suna da mahimmanci don sarrafa ƙididdigar layi a cikin haɗin formaldehyde, ba da damar samar da tsire-tsire na formaldehyde, masana'antun masana'antu, tsire-tsire na petrochemical, da tsire-tsire masu magani don cimma kyakkyawan aiki. Ta hanyar samar da ingantattun bayanai na lokaci-lokaci, waɗannan kayan aikin suna haɓaka yanayin amsawa, rage sharar gida, da tabbatar da bin ƙaƙƙarfan aminci da ƙa'idodin muhalli. Shin kuna shirye don haɓaka aikin samar da formaldehyde? Tuntuɓi lonnmeter don bincika mitoci masu haɓakawa waɗanda suka dace da bukatunku, buɗe aiki da inganci a cikin ayyukanku.

Lokacin aikawa: Juni-27-2025